Screen printing is one of the most commonly used printing techniques, especially for printing on fabrics and textiles. If you’ve ever received promotional merchandise, like tote bags, or T-shirts, the design was more than likely screen printed onto the fabric. In this guide, we’ll cover the screen printing process, where it all began and why it’s a popular option for many businesses.

What is screen printing?

Screen printing – also known as silk screening, silk screen printing or serigraphy – is a popular printing technique that works by pressing ink through a mesh screen onto the desired material. Firstly, a stencil is created on a fine mesh screen. This stencil is placed flat onto the material before ink is pressed through the screen. One colour is printed at a time, meaning screen printing can be used for multi-coloured designs.

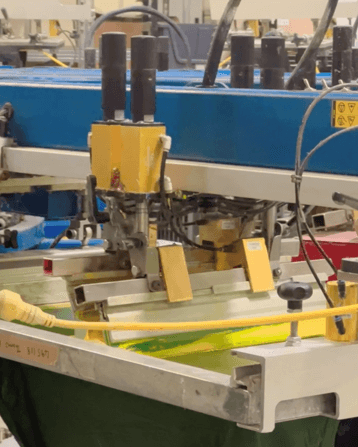

Although the ink can be manually pressed through using a squeegee, many commercial printers set the process up automatically using industrial machines, meaning they can print in bulk.

Fabric is the most common material for screen printing designs; other popular materials include wood, metal, plastic and glass.

Why is screen printing popular?

Screen printing has many benefits that make it the best option for printed merchandise. Unlike standard digital printing, screen printing allows you to create more vivid colours, even on dark materials.

The mesh screen stencils can be used over and over, making it easy to reproduce a single design multiple times. For this reason, screen printing is often used for work uniforms or sports team shirts where large batches of the garment are required.

Does screen printing fade?

Screen printing allows for a wide variety of colours – but does the effect last?

That largely comes down to two things:

- The curing process

- Aftercare

Once the ink has been pressed onto the material, the printed product is passed through a dryer and heat-cured, creating a smooth and long-lasting design which ensures the ink won’t fade away.

When properly washed and dried, the final print design should last the lifetime of the product. For items like T-shirts, it’s recommended that you wash them inside out to best preserve the print.

Is screen printing hard?

Screen printing is known for being a manual task that’s process and technique heavy. Nowadays can organise all your screen printing online, making it a much easier process. However, it is still possible to make your own DIY screen print products at home.

Screen printing at home can also be quite messy. It’s essential to make sure you set up your workspace in a clean and organised way before you start, ensuring that your work surface is protected from ink.

When you’re finished printing, immediately clean your equipment to keep it in good condition.

The easiest way to screen print your own products at home is using a pre-made screen which you can find at craft and hobby shops or online. Then all you will need is paint or ink and a brush, and a squeegee or something to add pressure to the print.

Apply paint evenly to the pre-made screen, then use a piece of paper to transfer the design onto the screen. Put the paper on top of the item you want to print on and apply pressure to transfer the design onto the printed product.

What are the different types of screen printing?

There are 6 different types of screen printing, each producing a different effect. Here’s a little bit about each method to help you decide which is best for your print needs:

1. Spot colour screen printing

This is the most commonly used technique for screen printing and involves using premixed ink colours. This pre-mixed ink colour is simply pressed through the mesh screen, leaving a vibrant finish. This is often more affordable than printing specific brand colours, but offers fewer customisation options.

2. Half-tone screen printing

This technique prints a single colour in a gradient. This is a cost-effective way to achieve a multi-tonal design without paying extra for multiple ink colours.

3. Greyscale screen printing

Similar to half-tone printing, greyscale (or grayscale) printing prints a full-colour image using only greyscale. Rather than being just solid black and white ink, this technique also produces shades of grey as a gradient and is often used for printing black and white T-shirt and other print designs.

4. Duotone screen printing

Duotone printing combines two half tones. A black halftone is printed onto the garment first, followed by a second halftone which uses a colour ink. This creates an almost sepia-toned effect.

5. CMYK screen printing

This type of screen printing uses the four basic ink colours in printing – cyan, magenta, yellow and black (key). These colours are combined in varying amounts to create different colours, allowing for a more personalised design.

6. Simulated process printing

For photorealistic printing, simulated process printing produces the best effect. That’s because it combines the spot colour and four-colour printing processes to create a range of colours and shades.

Screen printing vs embroidery

For any business considering printed garments, one of the decisions they’ll need to weigh up is screen printing or embroidery. The better option depends entirely on what you want to print.

Cost

In terms of price, either option can be the more affordable one. For embroidery, you’ll be looking at a flat rate no matter how many colours your design includes. For screen printing, you’re likely to have to pay more for four-colour or CMYK printing compared with a single-colour or half-tone print.

Large logos and designs are also more likely to be cheaper screen printed compared with embroidered logos.

Material

While embroidery looks great on heavier garments like polo shirts, thinner materials such as polyester and cotton T-shirts may cause the stitching to pucker.

For thin, stretchy garments, screen printing is the better option as it doesn’t create tension in the material.

Can screen printing be removed?

If you’ve made a mistake with your print or have found a screen-printed item that you’d prefer not to be printed, you can remove the design with a bit of elbow grease.

The easiest method to remove screen printing from clothing is soaking a cotton ball or pad in an acetone-based nail varnish remover and rubbing the print away. Remember to test the nail polish remover on an unobtrusive part of the fabric to ensure it won’t damage your product first!

How to do your own screen printing

If you’d like to screen print your logo onto promotional merchandise and safety vests or create a custom tote bag with your own design on it, the easiest way to do this is by ordering it online. Not only does this take the effort, time and mess out of the equation, but it’s also cost-effective – especially if you’re ordering in bulk. Check out our promotional merchandise range to get started with screen printing today.

.png)