Here at instantprint, we’ve made it our mission to help everyone create print that looks amazing – no matter what your experience or skills are.

If you’ve ever found yourself googling DPI or GSM or any of the terminology that pops up in the print process (and we don’t blame you – there’s a lot!), you’re not alone. We realise that a lot of these terms aren’t used in everyday life, so we’ve come up with the ultimate guide to help you master your print-speak so your next order will be a breeze!

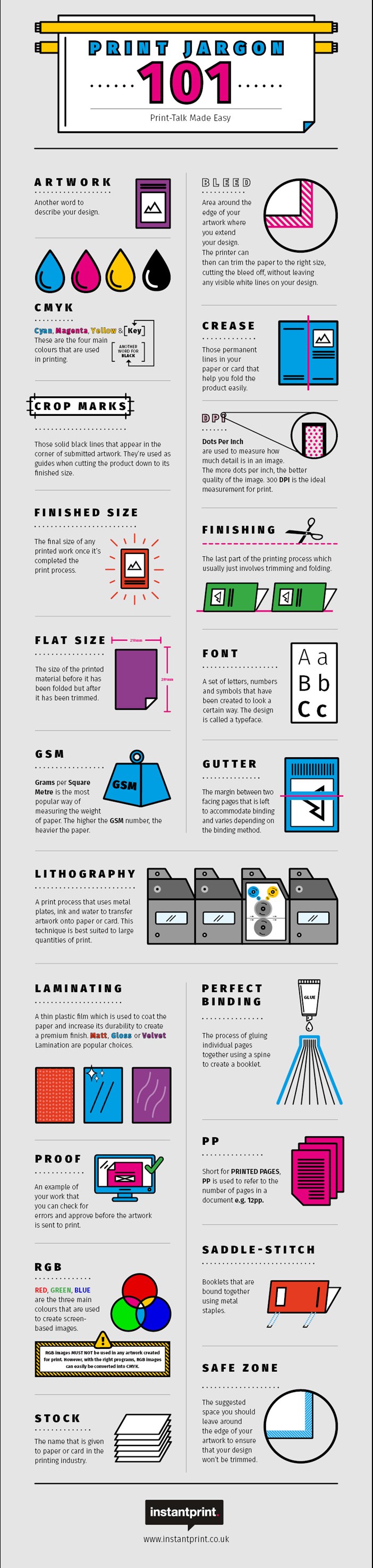

Here’s our quick, one-stop printing glossary so you’ve got all the definitions you might need all in one place.

Artwork

This is another word for your design. This is the file you’ll need to send to us to print.

Bleed

Area around your artwork where you extend your design. The printer can then trim the paper to the right size, trimming off the bleed area so there are no white borders left on your finished design where the cutters might be a mm off here or there.

CMYK

Cyan, Magenta, Yellow and Key (Black) – these are the ink colours commercial printers like ours use to print your design.

Crease

The permanent lines, or folds, in your paper or card that help you easily fold your print. For many of our products, like folded leaflets, greetings cards and presentation folders, we’ll pre-crease or pre-fold them so they’re fully assembled when you get them.

Crop Marks

When you submit your artwork, you might notice solid black lines that appear on the corners. They’re used as guides when cutting the printed design down to size. Please don’t add these to your artwork – we’ll set them up using our own system that works with our printers.

DPI (Dots per Inch)

Dots, or pixels, per inch are used to measure how much detail is in a picture, and therefore how high the resolution of that picture is. The more dots per inch, the more detail in the picture, and the better your design will look once it’s printed. 300dpi is usually the ideal resolution for printing.

Finished Size

The final size of your print product after it’s been through the whole printing process – so the size it’ll be when it arrives at your door!

Finishing

The last part of the printing process. Usually involves trimming, folding and binding – depending on the printed item.

Flat Size

The size of the printed material before it’s been folded but after it’s been trimmed.

Font

A set of letters, numbers and symbols that have been created to look a certain way. The design is called a typeface.

GSM

Grams per square metre is the most popular way of measuring the weight of paper (although you may come across others like microns). The higher the GSM number, the heavier the paper.

Gutter

The margin between two facing pages that is left to accommodate binding and varies depending on the binding method – for example, perfect binding for booklets requires more gutter area than binding books with wire.

Lithography

A print process that uses metal plates, ink and water to transfer artwork onto the paper. This technique is best suited to long runs (AKA large quantity orders).

Laminating

A thin plastic film which is used to coat the paper and increase its longevity and create a premium look and feel. We offer matt, gloss and velvet lamination, each giving a very unique texture to your print.

Perfect Binding

The process of gluing individual pages together and binding them to a spine to create a booklet.

Proof

An example of what your artwork will look like when printed, so you can check for errors before approving the finished design for print.

PP

Short for printed pages, PP refers to the number of pages in a document, including covers. A printed page is a side of a page, for example a greetings card is one piece of card folded in half but has 4pp – a front cover, two inside sections and a back cover.

RGB

Red, green and blue are the main colours used to create screen-based images. This colour spectrum is much larger than CMYK, meaning some of the colours on your screen look different when printed.

Saddle Stitch

Booklets that are bound together with a metal staple – this is how our stapled booklets are made.

Stock

This is the material your artwork is printed on, for example paper, card or PVC.

Safe Zone

The suggested space you should leave around the edge of your artwork to ensure that your design won’t be trimmed. We recommend keeping important information at least 3mm away from the edge.

If there’s anything we’ve missed or if you need help with any other part of the print process, get in touch, we’re always happy to talk it through!

(1).png)

.jpg)